Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

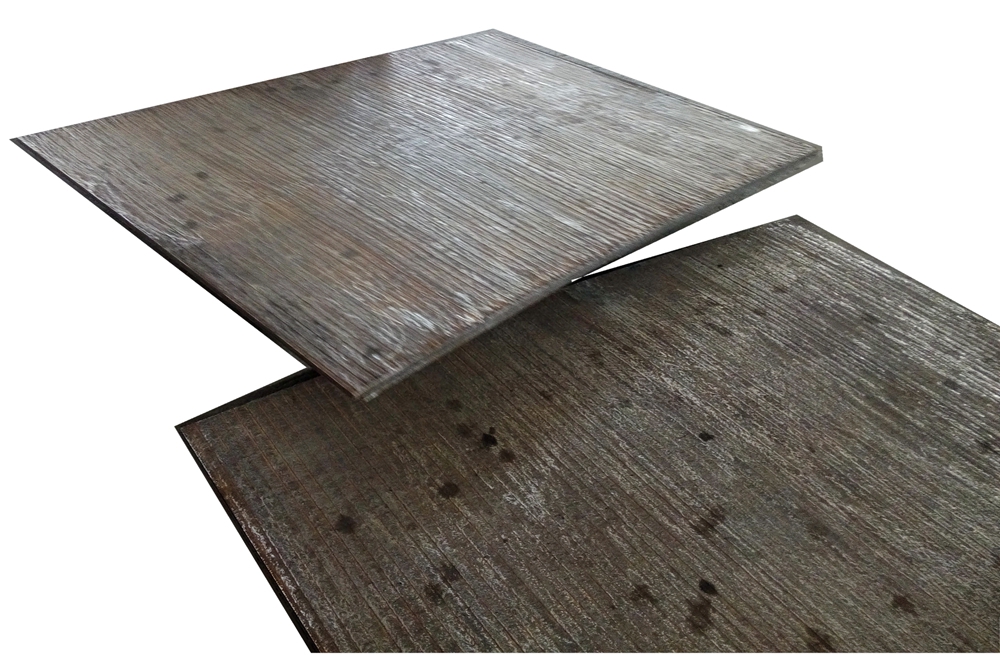

HP Wear Plate is an adjustable wear-resistant plate, which is produced by HUIFENG Wear Resistant Group. HP wear-resistant steel plate has good wear resistance and impact force. It can be cut, bent, welded, etc., and can be connected to other structures by welding, plug welding, bolt connection, etc. HP Abrasion Resistant Plate is widely used in metallurgy, coal, cement, electric power, glass and other fields.

It is suitable for complex working conditions of various impact, fatigue, polishing and wear. It can be widely used in scrapers, conveyors, loader, troughs, material warehouse linings, rolling mill linings and heavy truck partitions, mine crushers, water pipelines, engineering vehicles, excavators and other mining and coal mining machinery fields.

HP Chromium Carbide Overlay Plate could increase the hardness of the reinforcement layer under the medium and low impact load, and the impact fatigue resistance will also improve the wear resistance as the impact load increases.

HP wear-resistant steel has good processing performance and welding performance. It does not need preheating before welding and no heat treatment after welding. Surfacing wear plate manufacturers believe that this is an excellent feature that other wear plates at home and abroad do not have.

This grade of Wear Plates have good welding process performance, can use MIG welding (MIG) method for automatic welding, stable process and stable performance.

No need to preheat before welding just to clean the welding groove, choose the welding material correctly, and choose the shielding gas correctly.

The welding heat input is 12kJ/cm, the temperature between the passes is strictly controlled (150°C), the multi-layer multi-weld is used, and the water-cooled welding seam is used in time between the passes to ensure the welding performance.

Post-welding treatment: No heat treatment is required after welding, and it can be properly hammered to eliminate welding stress.

The base material of the composite board requires good toughness and weldability, and the price is moderate. According to market research and analysis, compared with other structural steel materials, Q23s steel has moderate carbon content, good comprehensive performance, and relatively good strength, plasticity and weldability. Therefore, Q23s carbon structural steel is used as the base material of the composite plate.

Since the yield strength and tensile strength of these four Q23s steels are the same, the chemical composition is slightly different. Considering the cost problem, we choose Q23sA as the base material of the composite board.

About the selection of welding wire

Through repeated tests, we selected the flux-cored wire D9s open arc surfacing welding wire developed by Beijing Welding Materials Co., Ltd. The chemical composition of the deposited metal of the welding wire is Cr-Fe-C type high-chromium alloy material. The chromium content of 22%~27% and the carbon content of 3.0%~5.0% can form Cr7C3 carbides with a volume fraction of more than 50% in the surfacing layer.

In the alloy structure, carbide is the hard phase in the composition (the microhardness of carbide is HV1300-1800). There are a large number of carbide phases in the structure of the surfacing layer, which makes the abrasive grains pressurized during the wear process. and friction are strongly hindered. At the same time, the eutectic structure has a suitable strength combination with the carbide, which makes the carbide not easy to fall off, which is equivalent to embedding high-hardness particles on the strong matrix. Especially in the welding process, we use a process to make the carbide grow. The direction is perpendicular to the plate surface, so the entire surfacing layer has excellent anti-abrasive wear performance.

June 01, 2023

October 14, 2022

October 14, 2022

Wyślij je do tym dostawcy

June 01, 2023

October 14, 2022

October 14, 2022

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.