Rodzaj płatności:L/C,T/T,D/P,D/A,Paypal,Others

Incoterm:FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU

transport:Ocean,Land,Air

Porta:Shanghai,Qingdao,Shenzhen

$1100-99Kilogram

$9.9≥100Kilogram

Model No: Wear Plate-HP700

Marka: Płyta HP, spawanie HP

Standard: AiSi, ASTM, bs, HAŁAS, GB, JIS

Miejsce Pochodzenia: Chiny

Gatunki: Blachy stalowej

Proces Produkcji: Walcowane na zimno

Obróbka Powierzchniowa: Pokryty

Podanie: Płyta kołnierzowa

Stal Specjalna: Stal odporna na ścieranie, Płyta stalowa o wysokiej wytrzymałości

Tolerancja: ± 1%

Kategoria: Blacha stalowa walcowana na zimno, Blacha stalowa ocynkowana ogniowo, Płyta niskostopowa, Blacha stalowa powlekana kolorem, Blacha stalowa walcowana na gorąco, Blachy stalowej

Usługa Przetwarzania: Pochylenie się, Spawalniczy, Odwijanie, Ciąć, Wykrawanie

Standard Size 1: 4.92' X 9.84' Or 1500 X 3000mm

Standard Size 2: 4.59' X 9.84' Or 1400 X 2900mm

Standard Size 3: 3.94' X 9.51' Or 1200 X 2400mm

Standard Size 4: 7.22' X 9.84' Or 2200 X 3000mm

Standard Size 5: 3.28' X 9.84' Or 1000 X 3000mm

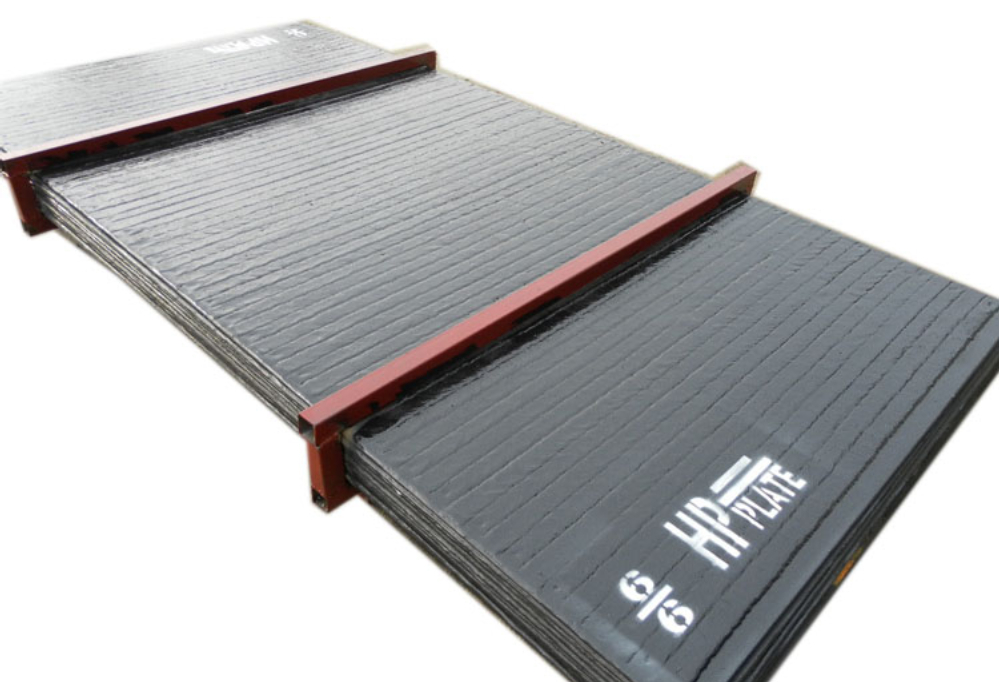

Standard Thickness 1: 2on3, 2on4, 3on3, 3on5, 4on6, 6on6

Standard Thickness 2: 7on8, 8on8, 9on10, 10on10, 12on12,10on20

Standard Thickness 3: 9on8, 12on8, 15on10,17on12, 20on12, 25on10

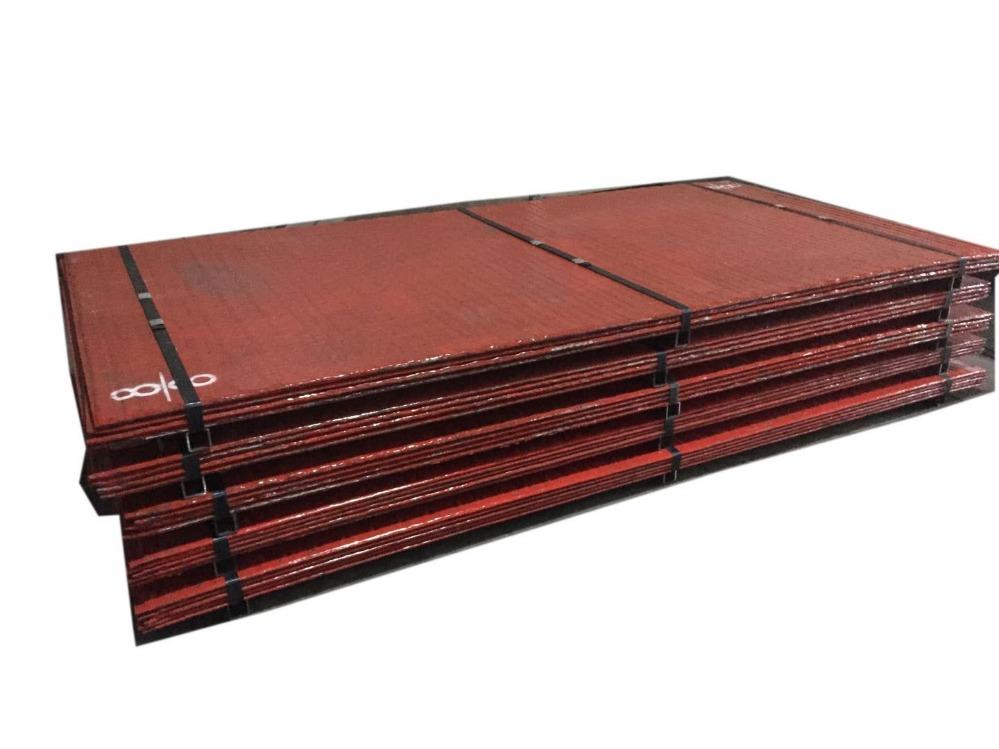

Packaging: Stalowa rama i pasek stalowy przymocowany

wydajność: 5000 tons

transport: Ocean,Land,Air

Place of Pochodzenia: Chiny

Wsparcie: 50,000㎡ wear plate per year

Certyfikat: ISO9001: 2015

Código HS: 72109000000

Porta: Shanghai,Qingdao,Shenzhen

Rodzaj płatności: L/C,T/T,D/P,D/A,Paypal,Others

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU

As a good compliment to Hardox Plate Hard Wearing Steel Plate like Chromium Carbide Overlay Plate performs very well combating with server abrasion in Cement Plant, Mining Site, etc… Such grade of Abrasion Resistant Plates is 3 to 4 times harder than ordinary structural plate and is easily weldable and can be formed and machined. Hardox Plate is available in thicknesses from 1/8" to 4", it can be cut by gas, abrasive water jet, laser or plasma. Hardox Steel and Arco Wear Plate can be used for various bulk material handling equipment.

Quick View On P roduct

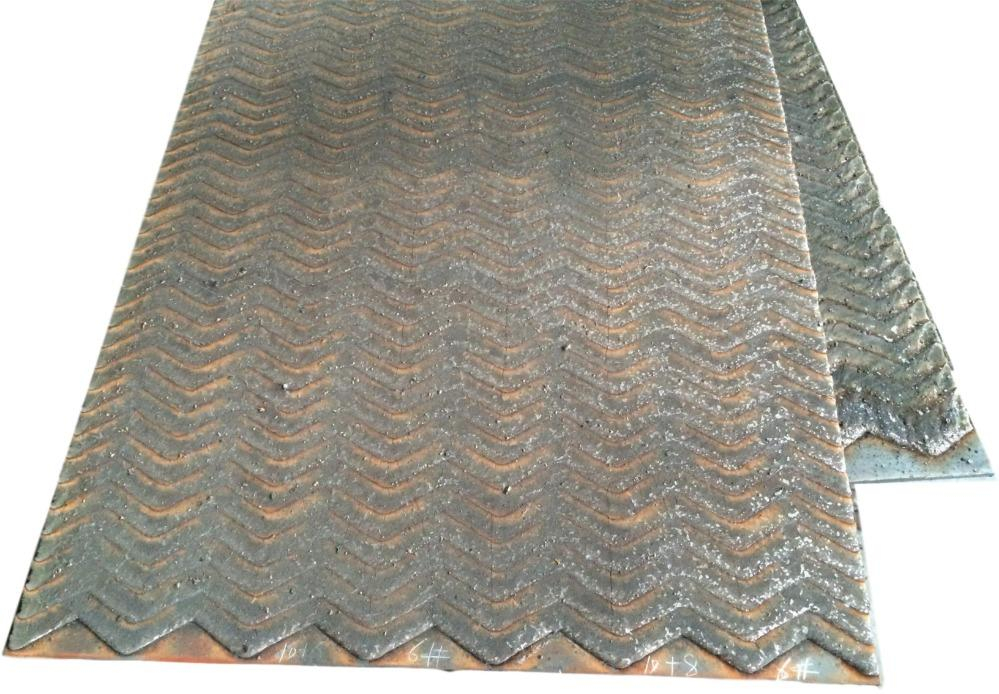

1. Product Name: HP Chromium Carbide Overlay Wear Plate

2. Body Material: A36 Mild Steel + Chromium Carbide Overlay (Hardfacing)

3. Grade: HP700, HP700S, HP750X, HP750P

4. Standard Size: 1200*2400mm; 1500*3000mm; 2200*3000mm or customised

5. Quality Standard: ASTM G65, AISI, ASTM, BS, DIN, GB, JIS

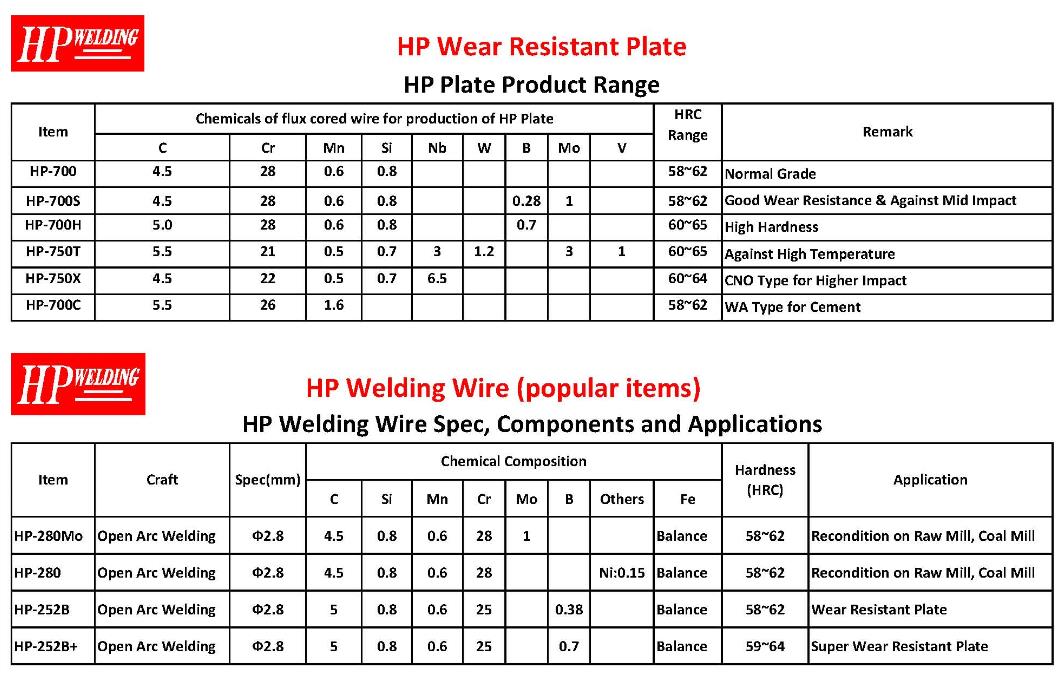

Standard Specifications of HP Wear Plate :

Packing & Delivery of Wear Plate

Packing Way: By Steel Tube, By Steel Belt, By Steel Pallet

Delivery Time: 20 days after order confirmation

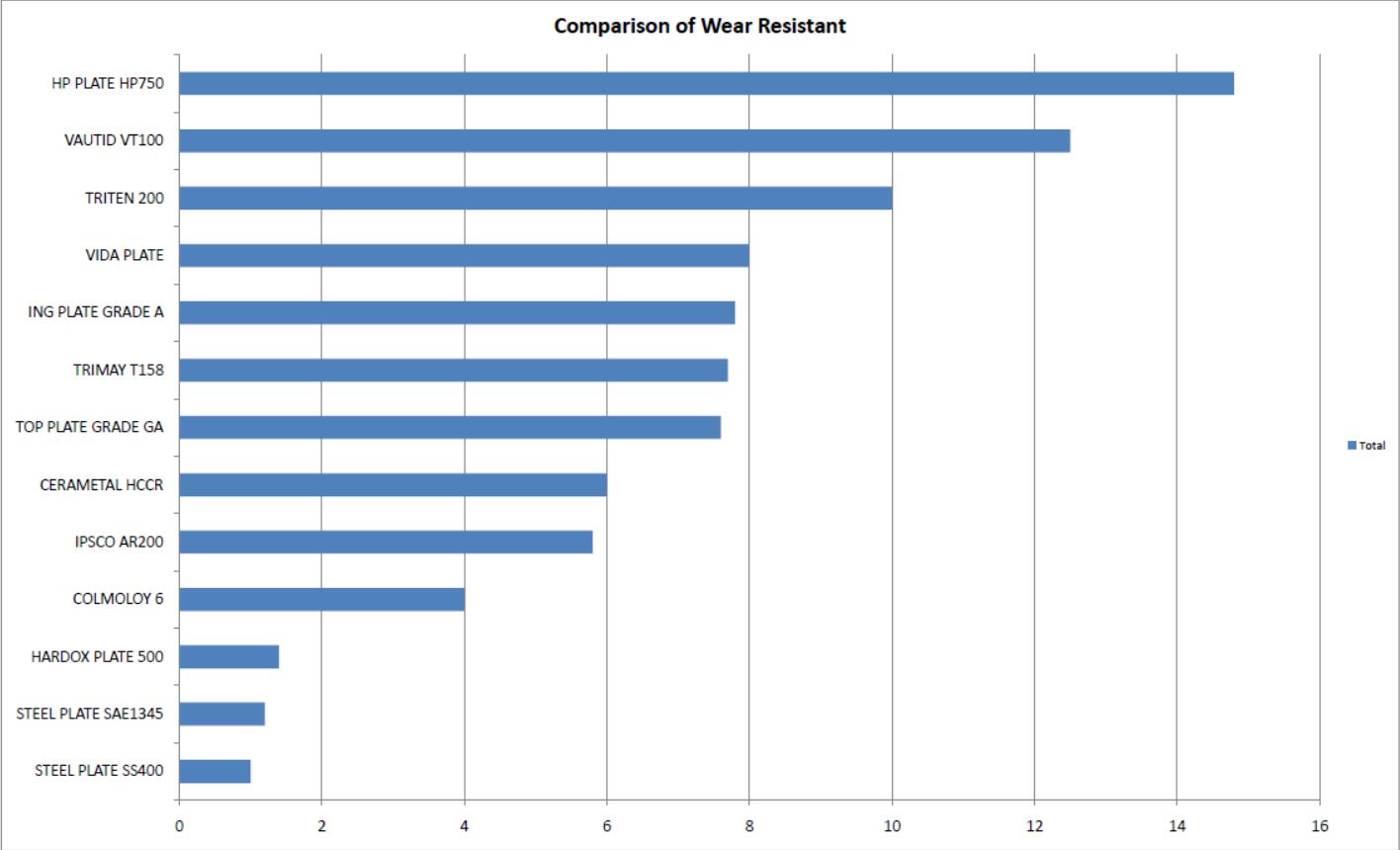

Anti-abrasion Comparison_HP Plate vs Other Plate

informacje o firmie

HP Plate (Huifeng Wear Resistant Industry Co., Ltd.) was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Plate has become the most experienced expert specializing in production and sales of wear resistant products.

HP Wear Products Range:

HP Wear Product Applications

Cement Plant, Mining Site, Steel Mill, Power Generation, Glass Industry,

Dredging, Surgar Industy, Quarry, Construction, etc...where need to be anti-abrasion.

HP Factory Laboratory

Company ISO Certificates:

FAQ On HP Wear Products

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Answer: It depends on the hardfacing alloy. Many chromium carbide alloys check-crack when cooled to moderate temperatures; to normalne. Other alloys, such as the austenitic and martensitic, do not crack when applied properly. Check cracking can be seen as cracking perpendicular to the bead length. This occurs by the high stress that is experienced when the weld metal cools. The cracking stops at the parent metal underneath, as long as the parent metal is not brittle. If the parent metal is hard or brittle, you should choose a buffer layer of a softer, and tougher, weld metal.

Question: What are the most popular applications with hardfacing products?

Odpowiedź: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.

Answer: Carbon and low-alloy steels with carbon contents of less than 1 percent can be hardfaced. High-carbon alloys may require a special buffer layer. Some of the base metals that can be hardfaced include: stainless steels, manganese steels, cast irons and steels, nickel-base alloys, copper-base alloys.

Question: What is hardfacing?